Most Popular Products

|

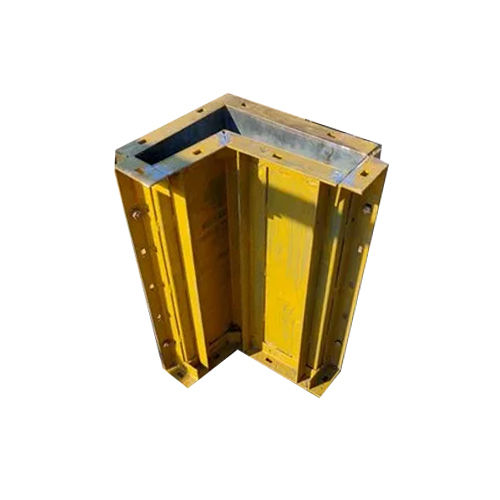

Mild Steel Precast Concrete Mould

Price 98 INR/ Kilograms

MOQ : 100 Kiloamperes

Mild Steel Precast Concrete Mould Specification

- Cavity

- Single or Multiple

- Molding Material

- Concrete

- Life Span

- 5-7 years depending on usage

- Mold Base

- Mild Steel

- Usage

- Industrial & Commercial

- Shaping Mode

- Precast Forming

- Material

- Metal

- Size

- 4 Feet

- Tolerance

- 1 mm

- Product Type

- Precast Concrete Mould

- Mould Weight

- Approx. 80-120 kg (varies with size)

- Color

- Yellow

- Mould Life

- 30,000-50,000 uses

- Assembly

- Welded Frame Structure

- Corrosion Resistance

- High

- Finishing Type

- Smooth

- Shape

- Rectangular/Customizable

- Surface Treatment

- Powder Coated

- Maintenance

- Low

Mild Steel Precast Concrete Mould Trade Information

- Minimum Order Quantity

- 100 Kiloamperes

- Payment Terms

- Cash in Advance (CID)

- Average Load Time

- 30-60 mins

- Supply Ability

- 10000 Kiloamperes Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Mild Steel Precast Concrete Mould

Mild Steel Precast Concrete Mould is a tool utilized to create concrete products or structures such as walls, columns, slabs, and beams in a factory or workshop setting. These moulds are made of mild steel, a common type of low-carbon steel that is easy to form and weld, and is known for its strength and durability. Apart from that, Mild Steel Precast Concrete Mould is designed to be reusable and can be used multiple times to create identical concrete products.

Superior Durability with High Corrosion Resistance

The powder-coated finish protects against moisture and chemical exposure, granting high corrosion resistance and extending the moulds life span. This ensures repeated, reliable usage in challenging industrial and commercial environments, reducing long-term costs.

Versatile Design for Custom Applications

Our molds are available in standard rectangular shapes or can be customized for specific project requirements. The welded frame structure provides strength and stability, accommodating single or multiple cavities for efficient concrete precasting.

Effortless Maintenance and Longevity

Thanks to low-maintenance features and robust mild steel construction, these moulds deliver consistent results with minimal upkeep. Intended for heavy use, each mould reliably supports between 30,000 to 50,000 cycles, lasting 5-7 years under typical conditions.

FAQs of Mild Steel Precast Concrete Mould:

Q: How is the Mild Steel Precast Concrete Mould maintained and what makes it low maintenance?

A: Maintenance is straightforward due to the powder-coated, smooth surface which resists concrete residue buildup. Routine cleaning with water and mild detergent is usually sufficient, and the high corrosion resistance means there is minimal need for frequent repairs or surface treatments.Q: What are the benefits of using a welded frame structure in these moulds?

A: A welded frame structure imparts superior stability and strength to the mould, reducing the risk of deformation or failure during the precasting process. This enhances consistency, safety, and longevity when used in industrial and commercial settings.Q: Where can these mild steel precast concrete moulds be used?

A: These moulds are designed for diverse industrial and commercial environments, including construction sites, precast factories, and infrastructure projects across India. Their robust build makes them suitable for high-volume and repetitive precasting operations.Q: When should I consider using single or multiple cavity moulds?

A: Single cavity moulds are ideal for producing larger or specialized precast pieces, while multiple cavity moulds boost efficiency by enabling simultaneous casting of several components. Selection depends on your production volume and specific project needs.Q: How long does each mould typically last and what influences its lifespan?

A: Each mould can withstand between 30,000 to 50,000 uses, translating to a practical life span of 57 years. Lifespan is influenced by usage frequency, handling, the abrasiveness of the concrete mix, and adherence to proper maintenance procedures.Q: What is the process for customizing mould shapes and sizes?

A: Customization is available to meet unique project specifications. Simply provide your required dimensions, shape preferences, and cavity needs to the manufacturer or supplier, who will design and fabricate the mould according to your guidelines.Q: What tolerance levels can be expected from these moulds during operation?

A: These moulds offer precise tolerance of 1 mm, ensuring accurate sizing and uniformity of precast concrete elements, crucial for meeting strict quality standards in industrial and commercial builds.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

PADMAVATI ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry